How Wirefield Engineered a Solution

Phase 1

In January 2014 Wirefield met with the Operations and Project Managers to present options and discuss solutions for lighting the newly acquired warehouse on the main site. It was determined they had looked at various proposals but were very keen to make use of the skylights for daylight control, in conjunction with the possibilities of dimming the lighting when presence was not detected. The new warehouse would not be occupied in all areas all of the time and therefore the combined effects of daylight and presence control could bring significant savings to the business.

Further discussions took place regarding whether to propose T5 or LED. The site has a long term plan for energy saving and energy efficiency and this, in conjunction with a long term plan for the site, resulted in the selection of the LED luminaire for the warehouse.

Phase 2

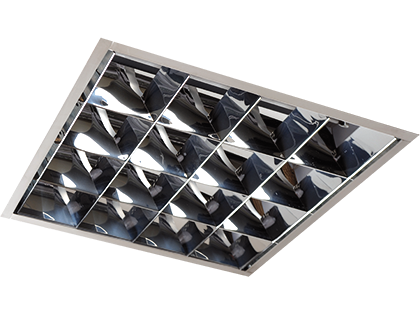

Following the installation of the warehouse lighting, the site undertook a complete refurbishment of their offices and toilets. This involved new flooring, ceiling grid, furniture and an upgrade to the aging T8 lighting. Following the success of the warehouse project Wirefield provided a new lighting scheme utilising LED panels and LED downlights all of which incorporated wireless dimming technology.

The offices benefit from significant natural daylight and, while the offices are occupied throughout the day, office work is limited at night. The wireless system replaces switches to control the lighting when and if it is required during the night shift operation.

Why LED?

When combined with lighting controls LED becomes a versatile solution with unrivalled energy saving potential:

- Uses 12% power when running at 10% light level

- 10% light level is 10 times emergency lighting level

- Wirefield EYE-WI system allows for component replacement rather than complete the fitting in the event of failure at the end of rated service life

- Wirefield uses European branded control gear and top rated LEDs ensuring durability, reliability and superior performance

Both the warehouse and offices required dimming and daylight control and the most cost effective solution to provide the required solution was to incorporate the EYE-WI wireless dimming technology.

Why Wireless?

The site was ideal for the wireless features and benefits:

- No additional wiring required for grouped operation. This allowed office luminaires to be grouped by area, and vary by area. Warehouse luminaires could be grouped down the racking aisles and across the open area regardless of circuit.

- No additional wiring required for new emergency lighting. This reduced the install time and cost. Without switches there is now only a permanent live supply.

- No knowledge of the existing wiring required

- Groups can be overlapped for multiple configurations on the same luminaires. This benefits the office luminaires which have an occupied and unoccupied profile – maximising energy savings

- Centralised reporting to the tablet of emergency failures. This allows for proactive maintenance rather than reactive, ensuring all luminaires are performing as specified

- Centralised occupancy reports to the tablet. This function allows the Operations Manager to monitor energy usage and review as appropriate.

- Site reconfiguration of luminaires as required

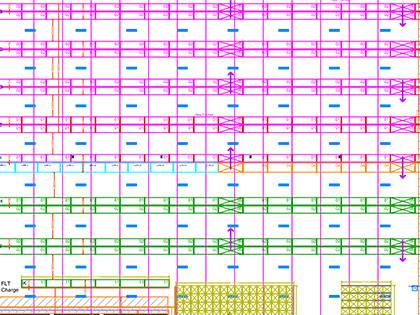

Site Survey, CAD Drawings and Designs

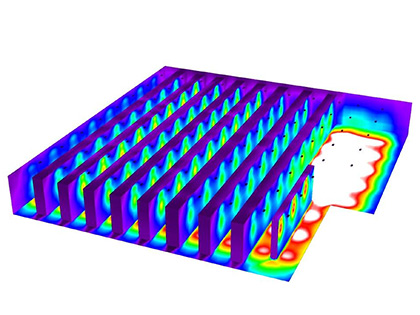

Both phase 1 and 2 had CAD drawings available and therefore a lighting design was supplied to indicate the expected light levels. All designs were completed to CIBSE guidelines.

The warehouse fittings were designed to suit the new racking installation and to provide both horizontal and vertical illumination. One of the key requirements was to provide illumination to facilitate correct picking of product.

A new 600x600 ceiling grid was being installed and the design was completed to comply with this, providing illumination over the central ‘virtual corridor’ and the desk space. Individual side offices were incorporated to give a uniform effect across the area. As a part of the phase 2 refurbishment, the toilets and reception area were also reviewed. LED downlights were utilised to improve the light levels while increasing service life and the aesthetic appeal of these areas.

Indicative level showing racking aisles and uniformly spaced luminaires

Motivators for Change

A new purchase and a refurbishment

The new warehouse had 2x70w batten luminaires running cross ways to the new racking. Therefore, these were both aging technology and no longer fit for purpose. The office luminaires were 1200x600 recessed modular and at the end of their service life. Furthermore, none of the current lighting could be presence or daylight controlled.

Energy savings

The site had a commitment to long term energy savings

Monitoring and Reviewing Usage

Eye-Wi system allows for constant modifications to luminaire settings as the areas change usage over time

Competitor Activity

Wirefield faced competition from another manufacturer offering a different LED and control solution. The rival proposal was based around a DALI control system which would have increased the install cost and installation time significantly. It would have also increased the complexity of the control system without any tangible benefits over the Eye-Wi system. In addition, Wirefield was questioned on the design criteria used requiring a justification of maintenance factors, emergency light levels and reference planes. All of the designs were completed to CIBSE guidelines and having attended site, accurate reflectances were provided to improve design reliability.

The Final Proposal, Installation and Results

The final proposals and solutions were offered in the first half of 2014.

- LED solution throughout with 100%-10%-0% dimmable control. 100w fittings were supplied in the warehouse and 33w LED panels throughout the offices.

- Daylight linking control to maximise savings

- Self testing emergency luminaires. All emergency fittings supplied report back to the tablet allowing accurate fault finding and a reduced maintenance solution

- Tablet provided to the site to allow commissioning and self set up of all luminaires

Payback Report - Warehouse

| Payback Period (yrs) | 3.2 |

|---|---|

| Annual Saving (%) | 87% |

| Annual Saving (£) | £7,124 |

| Annual CO2 Saving (tonnes) | 40 |

Electricity invoices and monitoring via the tablet have confirmed that the site is achieving savings fully in line with the projected values.

The two installations were completed and commissioned over separate 4 week install periods to allow the site to begin realising the energy savings and reduced maintenance promised throughout the process.

An Evolving Solution

The flexibility of the wireless system has allowed for a number of changes since initial commissioning. The office has been reconfigured so that the majority of fittings are turned off in the evening, during the night shift, to increase the energy savings even further. Only a virtual corridor of luminaires is left on for health and safety reasons. If the offices are required during the night, the settings have been altered so that fittings are illuminated for a shorter period of time. Furthermore, air conditioning units and toilet mirror lights have been linked to the system highlighting the flexibility and bespoke offering EYE-Wi can bring to the end user.